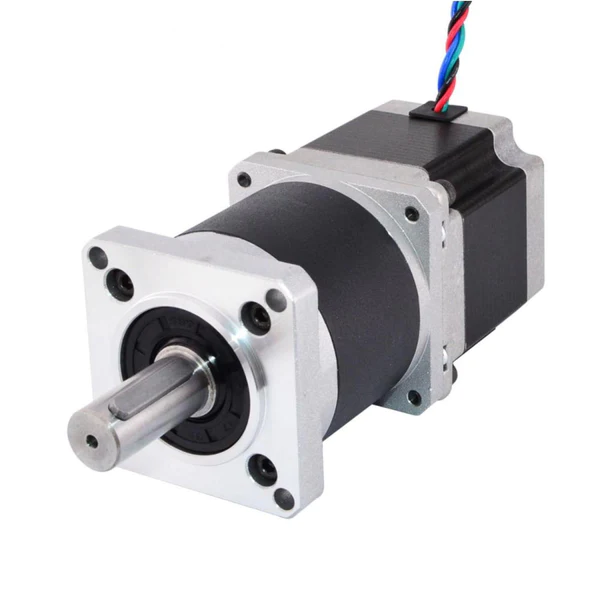

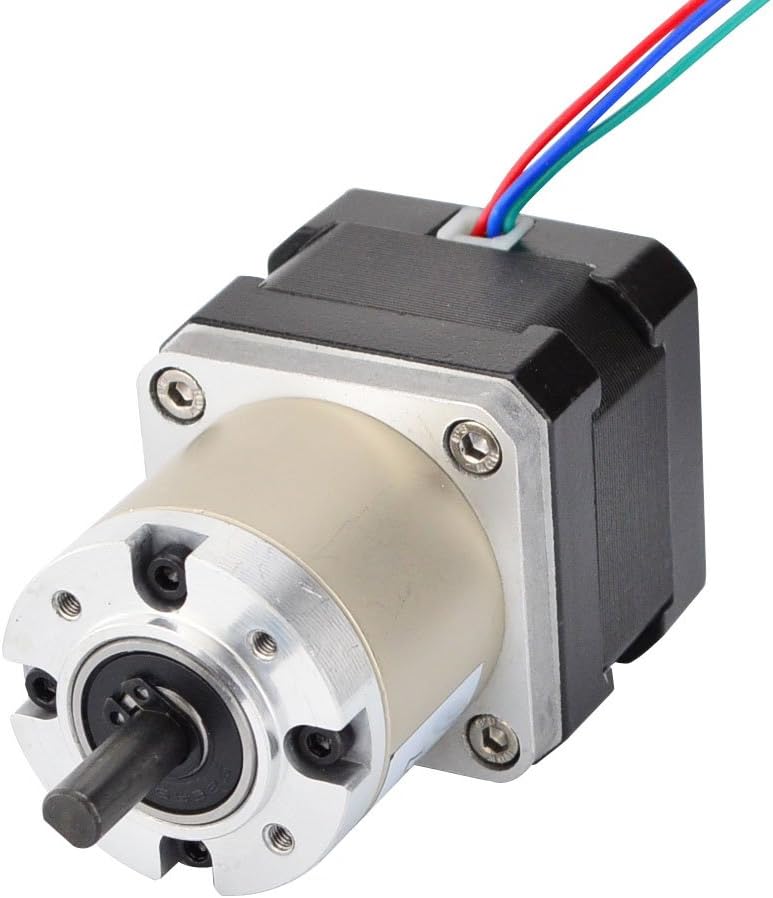

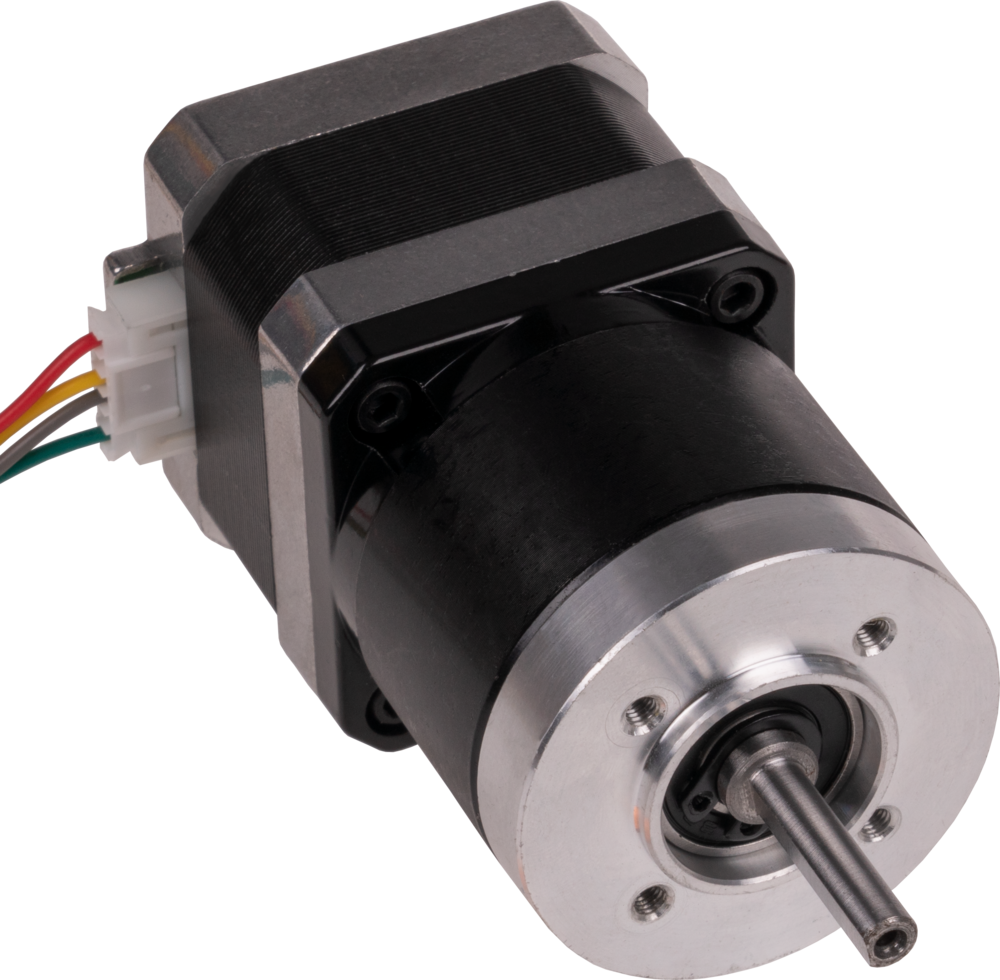

Product Description

|

Product Parameter

|

|

| Step Accuracy | ±5% |

| Temperature Rise | 80 °C Max |

| Insulation Resistance | 100MΩ Min.500VC DC |

| Ambient Temperature | 20°C~50°C |

| Dielectric Strength | 500VAc 1 minute |

| Max Radial Force | 75N (20mm from front flange) |

| Max Axial Force | 15N |

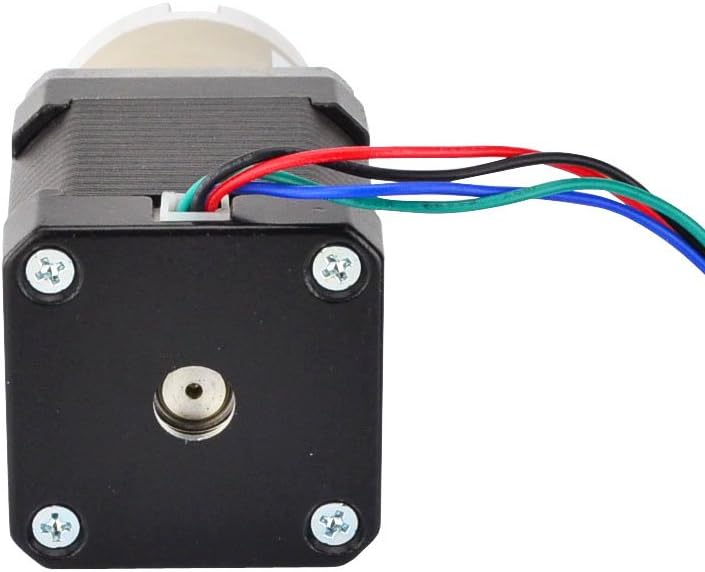

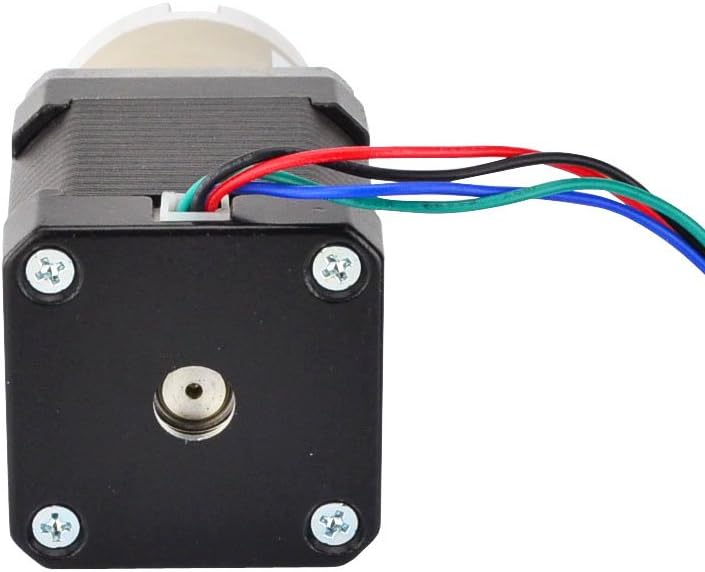

Detailed Photos

| Model | Step Angle |

Lead Wire (NO.) |

Rated Voltage (VDC) |

Current (A/Phase) |

Resistance (Ω/Phase) |

Inductance (mH/Phase) |

Holding Torque (Kg.cm) |

Motor Height L(mm) |

Motor Weight (Kg) |

| 57BGYHM002-01 | 0.9 | 6 | 2.8 | 2.0 | 1.4 | 2.0 | 3.5 | 41 | 0.45 |

| 57BGYHM200-03A | 4 | 3.4 | 1.0 | 3.4 | 12 | 7.0 | 51 | 0.56 | |

| 57BGYHM203-04 | 6 | 12 | 0.38 | 32.0 | 38 | 5.5 | 51 | 0.56 | |

| 57BGYHM401-09 | 6 | 7.4 | 1.0 | 7.4 | 17 | 9.0 | 56 | 0.70 | |

| 57BGYHM414 | 4 | 1.7 | 4.2 | 0.4 | 1.0 | 11 | 56 | 0.70 | |

| 57BGYHM604-17 | 4 | 3.2 | 2.8 | 1.13 | 6.4 | 15 | 78 | 1.00 | |

| 57BGYHM601-05 | 6 | 8.6 | 1.0 | 8.6 | 20 | 13 | 78 | 1.00 |

Products Application

Factory Shows

Chensite is a leading manufacturer with advanced technology and innovative management mode. Hetaispecializes in producing servo motors,Dc Motors,hybrid stepping motors,drivers and so on.

Chensite dedicates to professional electrical integration and automation strategies for customers. The products are almost applied in obots, packing machinery, textile machinery,medical instruments, printing machinery, intelligent logistics equipment Chensite also sends its products to USA, Europe,Southeast Asia and all-around China.

Certifications

FAQ

Q: What’re your main products ?

A: We currently produce Brushed Dc Motors, Brushed DC Gear Motors, Planetary DC Gear Motors, Brushless DC Motors, Stepper motors, AC Motors and High Precision Planetary Gear Box etc. You can check the specifications for above motors on our website and you can email us to recommend needed motors per your specification too.

Q: How to select a suitable motor ?

A:If you have motor pictures or drawings to show us, or you have detailed specs like voltage, speed, torque, motor size, working mode of the motor, needed lifetime and noise level etc, please do not hesitate to let us know, then we can recommend suitable motor per your request accordingly.

Q: Do you have a customized service for your standard motors ?

A: Yes, we can customize per your request for the voltage, speed, torque and shaft size/shape ,If you need additional wires/cables soldered on the terminal or need to add connectors, or capacitors or EMC we can make it too.

Q: Do you have an individual design service for motors ?

A: Yes, we would like to design motors Individually for our customers, but it may need some mold developing cost and design charge.

Q: What’s your lead time?

A: Generally speaking, our regular standard product will need 15-30days, a bit longer for customized products.

But we are very flexible on the lead time, it will depend on the specific orders.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Printing Equipment |

|---|---|

| Speed: | High Speed |

| Number of Stator: | Four-Phase |

| Excitation Mode: | PM-Permanent Magnet |

| Number of Poles: | 8 |

| Operate Mode: | Three-Phase Six-Step |

| Samples: |

US$ 19.9/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Advantages of Using a NEMA Gearbox in Industrial Applications

NEMA gearboxes offer several advantages for industrial applications. They provide precise speed reduction, torque multiplication, and motion control. Their compact and standardized design ensures compatibility and interchangeability. NEMA gearboxes are durable, resistant to shock and vibration, and capable of handling heavy loads. They contribute to efficient power transmission, reduced maintenance, and increased equipment longevity. Additionally, NEMA gearboxes support various mounting configurations, making them versatile for different setups.

Safety Precautions when Working with NEMA Gearboxes

When working with NEMA gearboxes, ensure the power is off and locked out to prevent accidental startup, wear appropriate personal protective equipment (PPE) such as gloves and safety glasses, follow manufacturer guidelines for installation and maintenance, avoid wearing loose clothing or jewelry that can get caught, work in well-ventilated areas to prevent exposure to fumes, and be cautious of sharp edges and moving parts. Training and proper safety procedures are crucial to prevent accidents and injuries.

Key Features of NEMA Gearboxes

NEMA gearboxes feature a standardized mounting interface that ensures compatibility with NEMA motors. They are designed to provide efficient power transmission, torque multiplication, and speed reduction. These gearboxes are constructed from durable materials, such as cast iron or aluminum, to withstand varying loads and conditions. They often include precision-machined gears for smooth operation and reduced noise. NEMA gearboxes come in various gear ratios to accommodate different speed and torque requirements. They also offer options for different mounting orientations and motor flange sizes. These features collectively make NEMA gearboxes versatile and suitable for a wide range of industrial applications.

editor by CX 2024-04-03

China Good quality Planetary Gear Reducer Flange Type Pad NEMA 11 14 Planetary Gearbox Gear Box cycloidal gearbox

Product Description

|

Model |

PAD064 |

|

Ratio |

70 |

|

Backlash |

P2 ( ≤8arcmin ) |

|

Rated Output Torque |

50 Nm |

|

Rated Input Speed |

5000 rpm |

|

Effciency |

≥97% |

|

Torsional Rigidity |

13 |

|

Lubrication |

Synthetic Grease |

|

Operating Temperature |

-15ºC~+90ºC |

|

Protection Temperature |

IP65 |

|

Mounting Position |

Any Direction |

|

Service Life |

22000 hours |

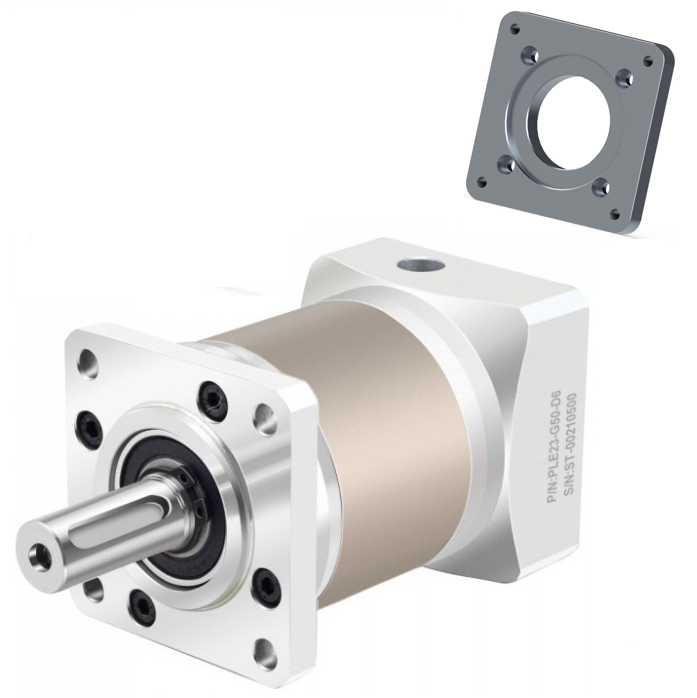

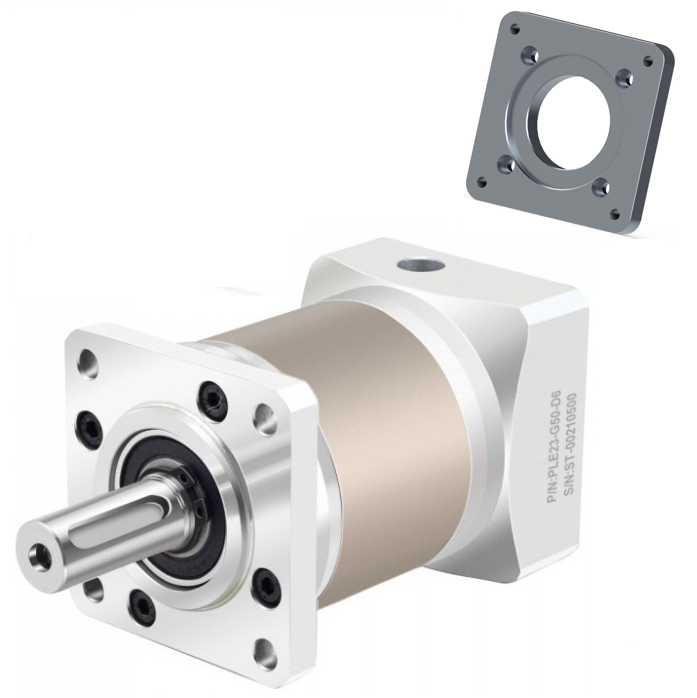

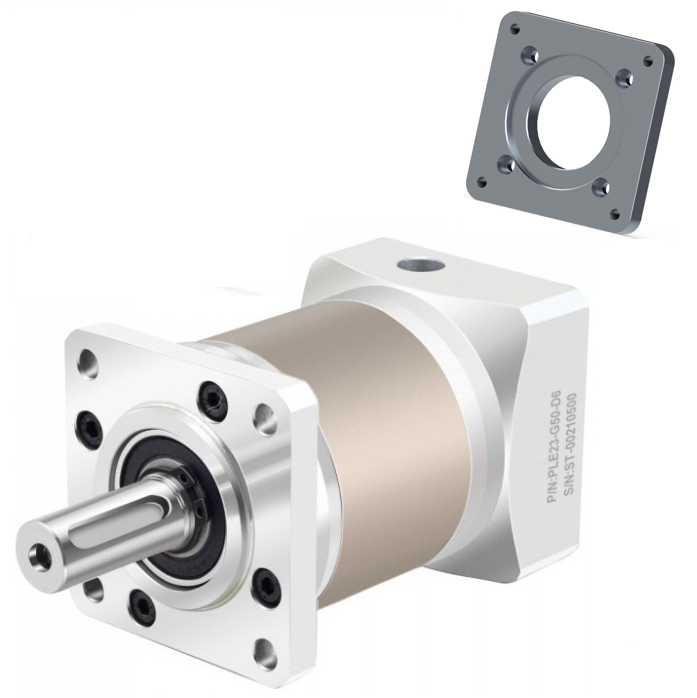

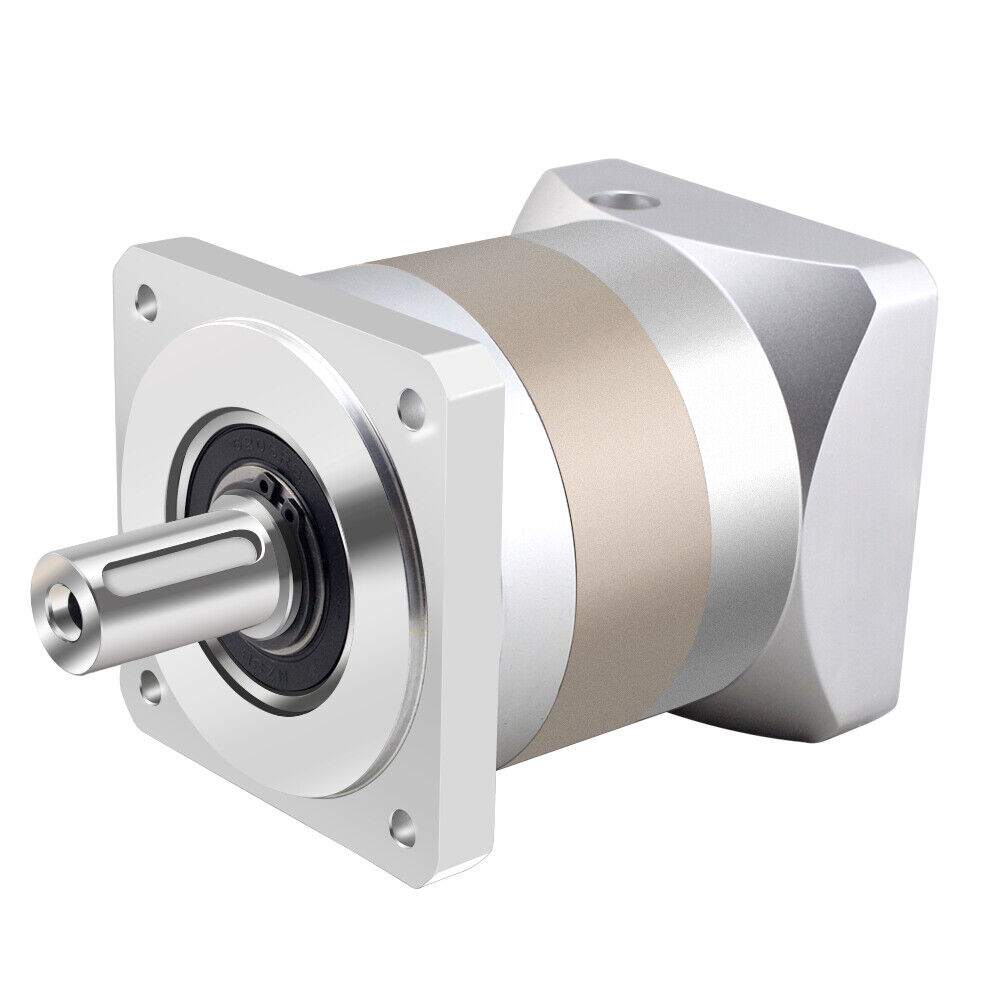

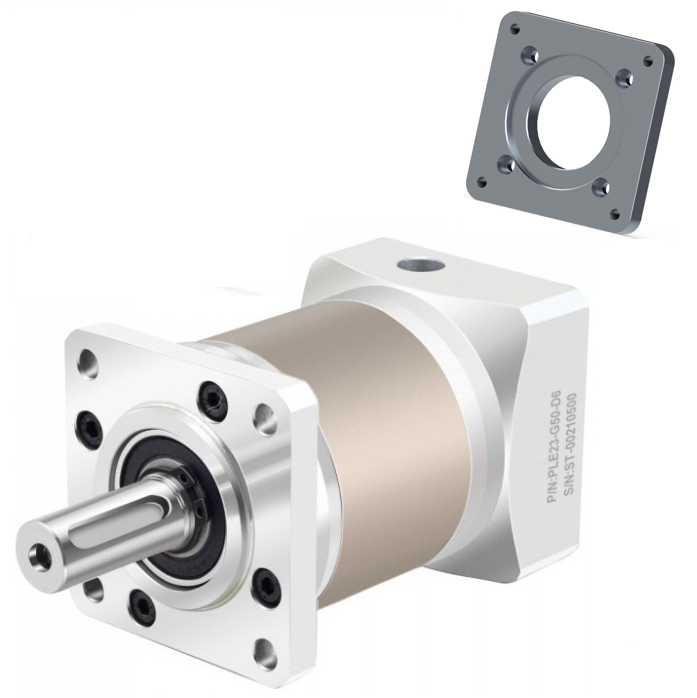

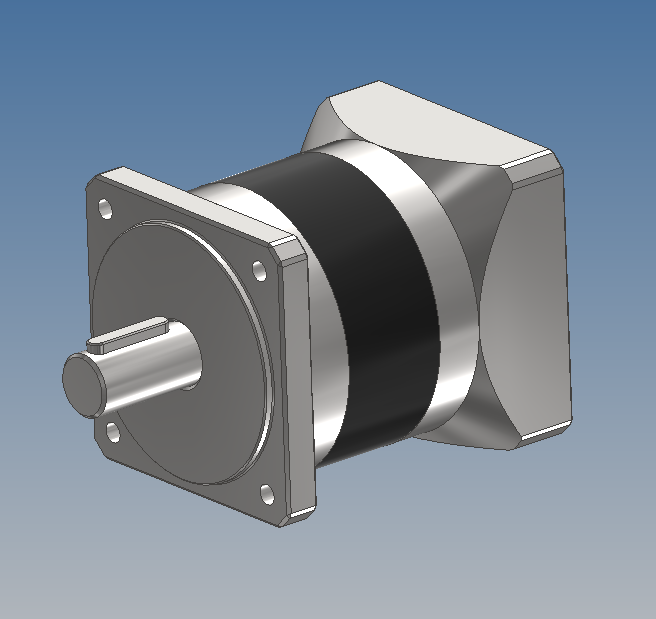

- Overview of PAD Planetary Gearbox

* PAD series features of high precision and low backlash

* 3F PAD series adopts integral ball bearings to realize high rigidity and high torque

* Due to the use of tapered needle roller bearing, it achieve the high load capacity.

* The PAD Speed reducer can be matched with any brands of motors.

* Free maintenance and long service life

Product Parameters

Detailed Photos

14 types of speed building ratio:=4-100

Minimum return interval: P0, P1P2

Maximum output torque: 23N. m-650N. m

Extremely high torsional rigidity and excellent performance

The highest load free policy is used in conditions with extremely high bearing capacity

Optimize power transmission and increase efficiency line by 98%

Very quiet during operation

Lifetime lubrication, no push protection

Fully sealed, IP65 protection level

Shortest structure and flexible installation

Small model: 64.90.110.140

Application

Product Description

Precision planetary gear reducer is another name for planetary gear reducer in the industry. Its main transmission structure is planetary gear, sun gear and inner gear ring.

Compared with other gear reducers, precision planetary gear reducers have the characteristics of high rigidity, high precision (single stage can achieve less than 1 point), high transmission efficiency (single stage can achieve 97% – 98%), high torque/volume ratio, lifelong maintenance-free, etc. Most of them are installed on stepper motor and servo motor to reduce speed, improve torque and match inertia.

Company Profile

Certifications

Packaging & Shipping

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Hardness: | Hardened Tooth Surface |

|---|---|

| Installation: | Vertical Type |

| Layout: | Coaxial |

| Gear Shape: | Planetary |

| Step: | Single-Step |

| Type: | Gear Reducer |

| Samples: |

US$ 100/Piece

1 Piece(Min.Order) | |

|---|

Cost of a NEMA Gearbox

The cost of a NEMA gearbox varies widely based on factors like size, type, brand, and features. Smaller, less complex models might start around $100, while larger and more specialized units can range from hundreds to thousands of dollars. Customization, additional accessories, and quality can also influence the price. It’s advisable to request quotes from suppliers or manufacturers for accurate pricing information.

Maintaining and Servicing a NEMA Gearbox

Maintaining and servicing a NEMA gearbox involves regular inspections, proper lubrication, and addressing any issues promptly. Follow the manufacturer’s maintenance schedule and guidelines. Keep the gearbox clean and free from debris, and check for any leaks or unusual noises. Lubricate according to specifications with the recommended lubricant. Replace worn or damaged parts, such as seals or bearings, as needed. Regularly monitor temperature and vibration levels. Proper maintenance can prolong the gearbox’s life and prevent costly breakdowns.

Choosing the Right Size NEMA Gearbox

When selecting a NEMA gearbox size for your application, consider factors such as the required torque, input speed, and output speed. Calculate the torque by multiplying the load’s force by the distance from the axis of rotation. Determine the input speed (motor speed) and desired output speed. Choose a gearbox with a gear ratio that matches your speed reduction or multiplication needs. Check the gearbox’s torque and speed ratings to ensure they align with your requirements. Consider the service factor, which accounts for the application’s operating conditions. You may need to consult gearbox manufacturer catalogs and technical support to find the optimal size for your specific application.

editor by CX 2024-04-03

China OEM Nmrv050 Double Reduction Small Aluminium Helical Worm Drive Wheel Gear Reducer Motor Gearbox Interchange with NEMA 23 Worm Gearbox cvt gearbox

Product Description

nmrv050 double reduction small aluminium helical worm drive wheel gear reducer motor gearbox interchange with nema 23 worm gearbox

Product Description

We are a state-of-the-art manufacturing facility dedicated to the production of high-quality gearboxes, an essential element in power transmission and motion control across a wide array of industries. Our core expertise lies in crafting precision-engineered gearboxes that excel in reliability, efficiency, and durability.

Our gearbox offerings include a diverse range of designs from worm gears to planetary gears, helical gears, and spur gears, catering to various torque and speed requirements. Each gearbox is meticulously manufactured using premium materials such as alloy steels, cast iron, or specialized composites, ensuring optimal strength and resistance to wear and tear under heavy loads and challenging environments.

The design process at our factory adheres strictly to international standards and utilizes cutting-edge technology for precision machining and heat treatment processes. This guarantees exceptional dimensional accuracy, smooth operation, and low noise levels in all our gearboxes.

Furthermore, we understand the importance of customization in meeting unique industrial demands. Hence, we also provide bespoke solutions tailored to specific customer needs, ranging from customized ratios to specialized mounting arrangements and compatibility with various motor types.

In essence, by partnering with us for your gearbox requirements, you can expect not only top-notch products but also unparalleled technical support, competitive pricing, and on-time delivery. We take pride in being a one-stop destination for all your gearbox needs, providing a seamless integration into any application and delivering superior performance throughout the product lifecycle.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Agricultural Machinery, Car |

|---|---|

| Function: | Distribution Power, Clutch, Change Drive Torque, Change Drive Direction, Speed Changing, Speed Reduction, Speed Increase |

| Layout: | Coaxial |

| Hardness: | Hardened Tooth Surface |

| Installation: | Horizontal Type |

| Step: | Three-Step |

| Samples: |

US$ 9999/Piece

1 Piece(Min.Order) | |

|---|

Calculating Torque Requirements for a NEMA Gearbox

To calculate torque requirements for a NEMA gearbox, you need to consider factors like load type, speed, and efficiency. Use the formula: Torque (Nm) = (Power (W) × 1000) / (Speed (RPM) × Efficiency). Determine the required power and speed, and account for efficiency losses. Ensure that the calculated torque is within the gearbox’s rated torque capacity. It’s essential to factor in safety margins and dynamic loads for accurate results.

Design Principles of NEMA Gearbox

NEMA gearboxes are designed based on the National Electrical Manufacturers Association standards, focusing on compatibility with NEMA motors. They feature a compact and versatile design, often incorporating helical, worm, or bevel gear configurations. These gearboxes are built for efficiency, durability, and precision, ensuring reliable power transmission. Key design principles include precise machining, quality materials, accurate alignment, and efficient heat dissipation. NEMA gearboxes are engineered to meet the needs of various industries and applications while adhering to standardized dimensions for motor compatibility.

Choosing the Right Size NEMA Gearbox

When selecting a NEMA gearbox size for your application, consider factors such as the required torque, input speed, and output speed. Calculate the torque by multiplying the load’s force by the distance from the axis of rotation. Determine the input speed (motor speed) and desired output speed. Choose a gearbox with a gear ratio that matches your speed reduction or multiplication needs. Check the gearbox’s torque and speed ratings to ensure they align with your requirements. Consider the service factor, which accounts for the application’s operating conditions. You may need to consult gearbox manufacturer catalogs and technical support to find the optimal size for your specific application.

editor by CX 2024-04-03

China supplier Two Stage NEMA 34 Stepper Motor Reduction Planetary Gearboxes cvt gearbox

Product Description

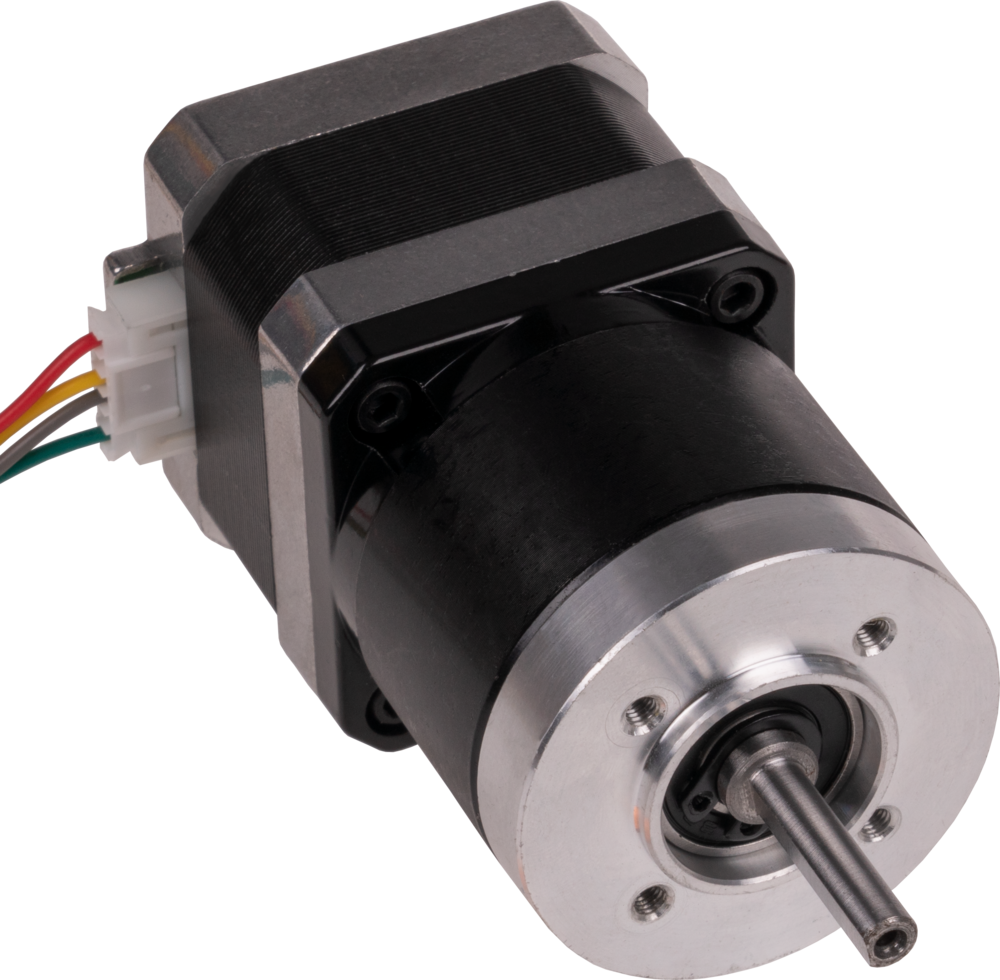

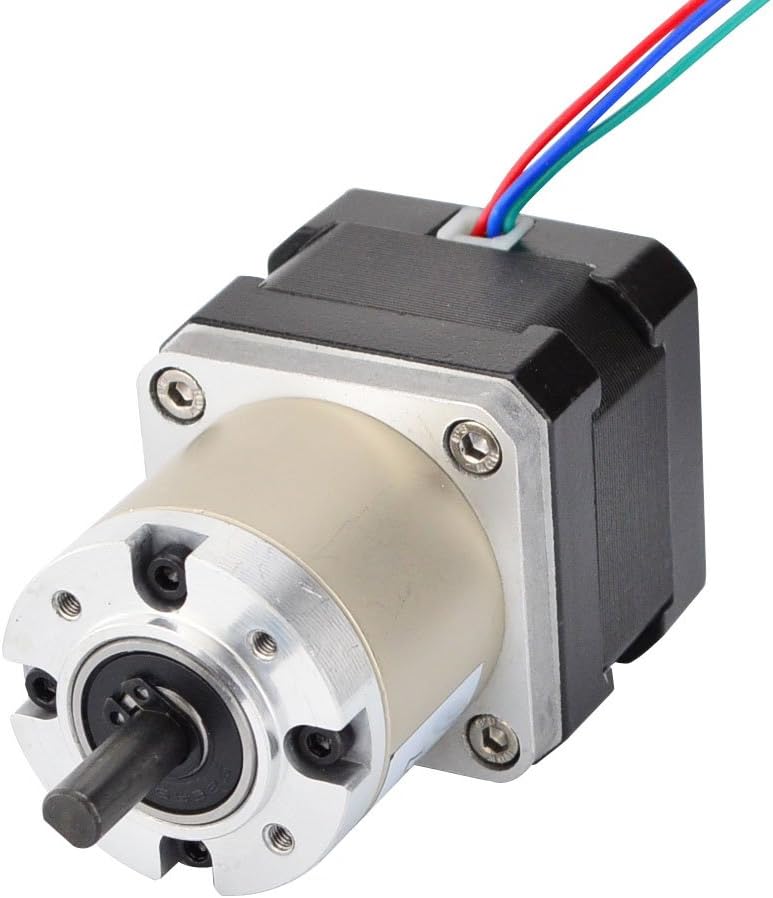

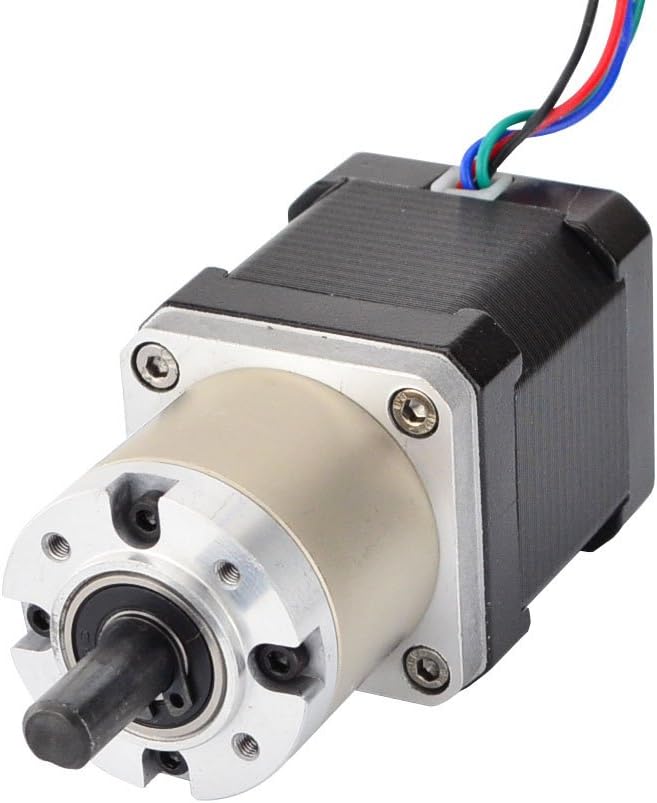

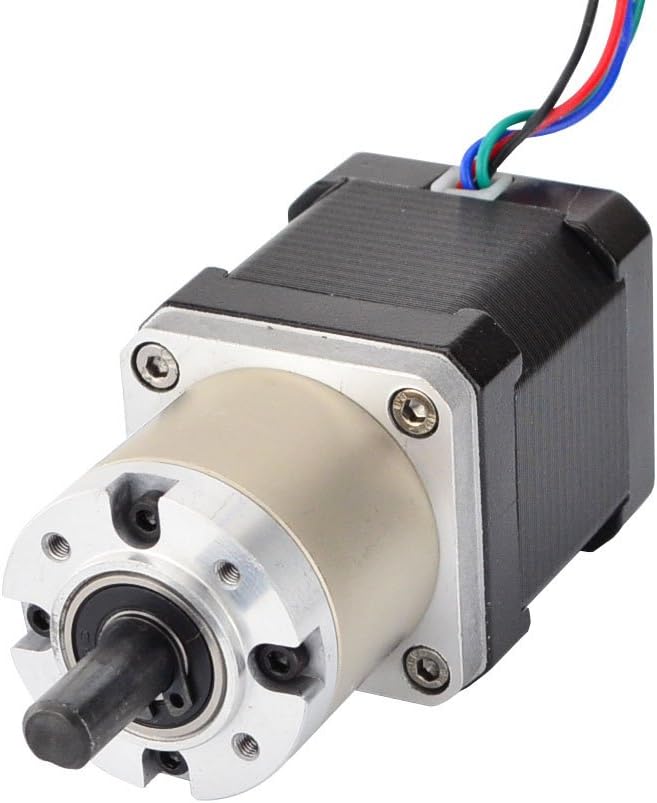

Two Stage Nema 34 Stepper Motor Reduction Planetary Gearboxes

This helical planetary gearbox is used for servo motor and related device which need to reduce speed or enlarge torque! CHINAMFG helical planetary gearboxes external diameter from 40 to 160, gear ratio from 3 to 100! It has high precision and are widely used with servo motor such like Panasonnic,Fuji, Mitsubishi, Omran,Delta, Teco.

Product Description

1.Output threaded connection, standard installation,universal usage.

2.Single cantilever structure.simple design,economic price

3.Working steady. Low noise.

4.Backlash 8-16 arcmin. Can suit most occasion

5.Keyway can be opened in the force shaft.

6.Round flange shaft output,threaded reverse connection,standardized size.

Product Parameters

| Specifications | PRL40 | PRL60 | PRL80 | PRL90 | PRL120 | PRL160 | |||

| Technal Parameters | |||||||||

| Max. Torque | Nm | 1.5times rated torque | |||||||

| Emergency Stop Torque | Nm | 2.5times rated torque | |||||||

| Max. Radial Load | N | 185 | 240 | 400 | 450 | 1240 | 2250 | ||

| Max. Axial Load | N | 150 | 220 | 420 | 430 | 1000 | 1500 | ||

| Torsional Rigidity | Nm/arcmin | 0.7 | 1.8 | 4.7 | 4.85 | 11 | 35 | ||

| Max.Input Speed | rpm | 8000 | 8000 | 6000 | 6000 | 6000 | 4000 | ||

| Rated Input Speed | rpm | 4500 | 4000 | 3500 | 3500 | 3500 | 3000 | ||

| Noise | dB | ≤55 | ≤58 | ≤60 | ≤60 | ≤65 | ≤70 | ||

| Average Life Time | h | 20000 | |||||||

| Efficiency Of Full Load | % | L1≥96% L2≥94% | |||||||

| Return Backlash | P1 | L1 | arcmin | ≤8 | ≤8 | ≤8 | ≤8 | ≤8 | ≤8 |

| L2 | arcmin | ≤12 | ≤12 | ≤12 | ≤12 | ≤12 | ≤12 | ||

| P2 | L1 | arcmin | ≤16 | ≤16 | ≤16 | ≤16 | ≤16 | ≤16 | |

| L2 | arcmin | ≤20 | ≤20 | ≤20 | ≤20 | ≤20 | ≤20 | ||

| Moment Of Inertia Table | L1 | 3 | Kg*cm2 | 0.1 | 0.46 | 0.77 | 1.73 | 12.78 | 36.72 |

| 4 | Kg*cm2 | 0.1 | 0.46 | 0.77 | 1.73 | 12.78 | 36.72 | ||

| 5 | Kg*cm2 | 0.1 | 0.46 | 0.77 | 1.73 | 12.78 | 36.72 | ||

| 7 | Kg*cm2 | 0.06 | 0.41 | 0.65 | 1.42 | 11.38 | 34.02 | ||

| 10 | Kg*cm2 | 0.06 | 0.41 | 0.65 | 1.42 | 11.38 | 34.02 | ||

| L2 | 12 | Kg*cm2 | 0.08 | 0.44 | 0.72 | 1.49 | 12.18 | 34.24 | |

| 15 | Kg*cm2 | 0.08 | 0.44 | 0.72 | 1.49 | 12.18 | 34.24 | ||

| 16 | Kg*cm2 | 0.08 | 0.44 | 0.72 | 1.49 | 12.18 | 34.24 | ||

| 20 | Kg*cm2 | 0.08 | 0.44 | 0.72 | 1.49 | 12.18 | 34.24 | ||

| 25 | Kg*cm2 | 0.08 | 0.44 | 0.72 | 1.49 | 12.18 | 34.24 | ||

| 28 | Kg*cm2 | 0.08 | 0.44 | 0.72 | 1.49 | 12.18 | 34.24 | ||

| 30 | Kg*cm2 | 0.08 | 0.44 | 0.72 | 1.49 | 12.18 | 34.24 | ||

| 35 | Kg*cm2 | 0.08 | 0.44 | 0.72 | 1.49 | 12.18 | 34.24 | ||

| 40 | Kg*cm2 | 0.08 | 0.44 | 0.72 | 1.49 | 12.18 | 34.24 | ||

| 50 | Kg*cm2 | 0.05 | 0.34 | 0.58 | 1.25 | 11.48 | 34.02 | ||

| 70 | Kg*cm2 | 0.05 | 0.34 | 0.58 | 1.25 | 11.48 | 34.02 | ||

| 100 | Kg*cm2 | 0.05 | 0.34 | 0.58 | 1.25 | 11.48 | 34.02 | ||

| Technical Parameter | Level | Ratio | PRL40 | PRL60 | PRL80 | PRL90 | PRL120 | PRL160 | |

| Rated Torque | L1 | 3 | Nm | / | 27 | 50 | 96 | 161 | 384 |

| 4 | Nm | 16 | 40 | 90 | 122 | 210 | 423 | ||

| 5 | Nm | 15 | 40 | 90 | 122 | 210 | 423 | ||

| 7 | Nm | 12 | 34 | 48 | 95 | 170 | 358 | ||

| 10 | Nm | 10 | 16 | 22 | 56 | 86 | 210 | ||

| L2 | 12 | Nm | / | 27 | 50 | 95 | 161 | 364 | |

| 15 | Nm | / | 27 | 50 | 96 | 161 | 364 | ||

| 16 | Nm | 16 | 40 | 90 | 122 | 210 | 423 | ||

| 20 | Nm | 16 | 40 | 90 | 122 | 210 | 423 | ||

| 25 | Nm | 15 | 40 | 90 | 122 | 210 | 423 | ||

| 28 | Nm | 16 | 40 | 90 | 122 | 210 | 423 | ||

| 30 | Nm | / | 27 | 50 | 96 | 161 | 364 | ||

| 35 | Nm | 12 | 40 | 90 | 122 | 210 | 423 | ||

| 40 | Nm | 16 | 40 | 90 | 122 | 210 | 423 | ||

| 50 | Nm | 15 | 40 | 90 | 122 | 210 | 423 | ||

| 70 | Nm | 12 | 34 | 48 | 95 | 170 | 358 | ||

| 100 | Nm | 10 | 16 | 22 | 96 | 80 | 210 | ||

| Degree Of Protection | IP65 | ||||||||

| Operation Temprature | ºC | – 10ºC to -90ºC | |||||||

| Weight | L1 | kg | 0.43 | 0.95 | 2.27 | 3.06 | 6.93 | 15.5 | |

| L2 | kg | 0.65 | 1.2 | 2.8 | 3.86 | 8.98 | 17 | ||

Company Profile

Packaging & Shipping

1. Lead time: 10-15 days as usual, 30 days in busy season, it will be based on the detailed order quantity;

2. Delivery: DHL/ UPS/ EMS/ TNT/ FEDEX

FAQ

1. who are we?

Hefa Group is based in ZheJiang , China, start from 1998,has a 3 subsidiaries in total.The Main Products is planetary gearbox,timing belt pulley, helical gear,spur gear,gear rack,gear ring,chain wheel,hollow rotating platform,module,etc

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3. how to choose the suitable planetary gearbox?

First of all,we need you to be able to provide relevant parameters.If you have a motor drawing,it will let us recommend a suitable gearbox for you faster.If not,we hope you can provide the following motor parameters:output speed,output torque,voltage,current,ip,noise,operating conditions,motor size and power,etc

4. why should you buy from us not from other suppliers?

We are a 22 years experiences manufacturer on making the gears, specializing in manufacturing all kinds of spur/bevel/helical gear, grinding gear, gear shaft, timing pulley, rack, planetary gear reducer, timing belt and such transmission gear parts

5. what services can we provide?

Accepted Delivery Terms: Fedex,DHL,UPS;

Accepted Payment Currency:USD,EUR,HKD,GBP,CNY;

Accepted Payment Type: T/T,L/C,PayPal,Western Union;

Language Spoken:English,Chinese,Japanese

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Motorcycle, Machinery, Marine, Agricultural Machinery, Machinery Parts |

|---|---|

| Function: | Change Drive Torque, Change Drive Direction, Speed Changing, Speed Reduction |

| Layout: | Coaxial |

| Hardness: | Hardened Tooth Surface |

| Installation: | Vertical Type |

| Step: | Double-Step |

| Samples: |

US$ 51/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Preventing Overheating in a NEMA Gearbox

To prevent overheating in a NEMA gearbox, you can take several measures. Proper lubrication is crucial to reduce friction and heat generation. Choose the right type of lubricant and ensure it’s at the correct level. Adequate ventilation around the gearbox is important, as well as avoiding external heat sources. Monitoring the gearbox’s temperature using sensors can provide early warnings. If the gearbox is consistently running at high temperatures, consider adjusting the load, gear ratio, or using a gearbox with a higher thermal capacity. Regular maintenance, including cleaning and inspecting cooling systems, can also help prevent overheating.

Common Problems Associated with NEMA Gearboxes

Common problems with NEMA gearboxes include overheating due to inadequate lubrication or excessive loads, leaks from worn seals or gaskets, abnormal noises caused by misalignment or damaged gears, and vibration issues due to imbalanced loads. Insufficient maintenance can lead to premature wear and reduced performance. Addressing these problems promptly through proper maintenance, regular inspections, and addressing issues as they arise can help prevent major damage and extend the gearbox’s lifespan.

Industries Using NEMA Gearboxes

NEMA gearboxes find applications in various industries such as manufacturing, food processing, packaging, material handling, textiles, robotics, agriculture, and more. They are used in conveyor systems, pumps, mixers, agitators, conveyors, and other machinery where reliable and efficient power transmission is essential. Their versatility and compatibility with NEMA motors make them a popular choice across different sectors.

editor by CX 2024-04-03

China Standard High Quality Planetary Gearbox Reducer High Speed NEMA 34 Planetary Gearbox supplier

Product Description

|

Model |

PAD064 |

|

Ratio |

70 |

|

Backlash |

P2 ( ≤8arcmin ) |

|

Rated Output Torque |

50 Nm |

|

Rated Input Speed |

5000 rpm |

|

Effciency |

≥97% |

|

Torsional Rigidity |

13 |

|

Lubrication |

Synthetic Grease |

|

Operating Temperature |

-15ºC~+90ºC |

|

Protection Temperature |

IP65 |

|

Mounting Position |

Any Direction |

|

Service Life |

22000 hours |

- Overview of PAD Planetary Gearbox

* PAD series features of high precision and low backlash

* 3F PAD series adopts integral ball bearings to realize high rigidity and high torque

* Due to the use of tapered needle roller bearing, it achieve the high load capacity.

* The PAD Speed reducer can be matched with any brands of motors.

* Free maintenance and long service life

Product Parameters

Detailed Photos

14 types of speed building ratio:=4-100

Minimum return interval: P0, P1P2

Maximum output torque: 23N. m-650N. m

Extremely high torsional rigidity and excellent performance

The highest load free policy is used in conditions with extremely high bearing capacity

Optimize power transmission and increase efficiency line by 98%

Very quiet during operation

Lifetime lubrication, no push protection

Fully sealed, IP65 protection level

Shortest structure and flexible installation

Small model: 64.90.110.140

Application

Product Description

Precision planetary gear reducer is another name for planetary gear reducer in the industry. Its main transmission structure is planetary gear, sun gear and inner gear ring.

Compared with other gear reducers, precision planetary gear reducers have the characteristics of high rigidity, high precision (single stage can achieve less than 1 point), high transmission efficiency (single stage can achieve 97% – 98%), high torque/volume ratio, lifelong maintenance-free, etc. Most of them are installed on stepper motor and servo motor to reduce speed, improve torque and match inertia.

Company Profile

Certifications

Packaging & Shipping

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Hardness: | Hardened Tooth Surface |

|---|---|

| Installation: | Vertical Type |

| Layout: | Coaxial |

| Gear Shape: | Planetary |

| Step: | Single-Step |

| Type: | Gear Reducer |

| Samples: |

US$ 100/Piece

1 Piece(Min.Order) | |

|---|

Preventing Overheating in a NEMA Gearbox

To prevent overheating in a NEMA gearbox, you can take several measures. Proper lubrication is crucial to reduce friction and heat generation. Choose the right type of lubricant and ensure it’s at the correct level. Adequate ventilation around the gearbox is important, as well as avoiding external heat sources. Monitoring the gearbox’s temperature using sensors can provide early warnings. If the gearbox is consistently running at high temperatures, consider adjusting the load, gear ratio, or using a gearbox with a higher thermal capacity. Regular maintenance, including cleaning and inspecting cooling systems, can also help prevent overheating.

Maintaining and Servicing a NEMA Gearbox

Maintaining and servicing a NEMA gearbox involves regular inspections, proper lubrication, and addressing any issues promptly. Follow the manufacturer’s maintenance schedule and guidelines. Keep the gearbox clean and free from debris, and check for any leaks or unusual noises. Lubricate according to specifications with the recommended lubricant. Replace worn or damaged parts, such as seals or bearings, as needed. Regularly monitor temperature and vibration levels. Proper maintenance can prolong the gearbox’s life and prevent costly breakdowns.

Key Features of NEMA Gearboxes

NEMA gearboxes feature a standardized mounting interface that ensures compatibility with NEMA motors. They are designed to provide efficient power transmission, torque multiplication, and speed reduction. These gearboxes are constructed from durable materials, such as cast iron or aluminum, to withstand varying loads and conditions. They often include precision-machined gears for smooth operation and reduced noise. NEMA gearboxes come in various gear ratios to accommodate different speed and torque requirements. They also offer options for different mounting orientations and motor flange sizes. These features collectively make NEMA gearboxes versatile and suitable for a wide range of industrial applications.

editor by CX 2024-04-02

China factory Multi Stage Planetary Gearbox Inline Epicyclic Gear Reduction Drive NEMA Hydraulic Single Sun Planet Epicyclic Micro Motor Two Stage Precision Bevel Planetary with high quality

Product Description

Multi stage planetary gearbox inline epicyclic gear reduction drive nema hydraulic single sun planet epicyclic micro motor 2 stage precision bevel planetary

Application of planetary gearbox

Planetary gearboxes are used in a wide variety of applications, including:

- Machine tools: Planetary gearboxes are used in machine tools to provide high torque and low speed. This is necessary for operations such as milling, drilling, and turning.

- Robotics: Planetary gearboxes are used in robotics to provide precise motion control. This is necessary for operations such as pick-and-place, assembly, and welding.

- Lifting equipment: Planetary gearboxes are used in lifting equipment to provide high torque and low speed. This is necessary for operations such as lifting and lowering loads.

- Wind turbines: Planetary gearboxes are used in wind turbines to convert the rotational motion of the turbine blades into electrical power.

- Electric vehicles: Planetary gearboxes are used in electric vehicles to transmit power from the motor to the wheels.

- Other: Planetary gearboxes can also be used in a variety of other applications, such as cameras, printers, and food processors.

Planetary gearboxes are a type of gear reducer that uses a planetary gear train to transmit power. Planetary gear trains are compact and efficient, and they can be used to achieve a wide range of gear ratios. Planetary gearboxes are available in a variety of sizes and configurations, and can be customized to meet the specific requirements of an application.

Here are some of the advantages of using planetary gearboxes:

- Compact: Planetary gearboxes are relatively compact, which makes them ideal for applications where space is limited.

- Efficient: Planetary gearboxes are very efficient, meaning that they can transmit a lot of power with a relatively small amount of input power.

- Reliable: Planetary gearboxes are very reliable and can withstand a lot of wear and tear.

- Versatile: Planetary gearboxes can be used in a variety of applications, making them a versatile option for power transmission.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Toy, Agricultural Machinery, Car |

|---|---|

| Function: | Distribution Power, Clutch, Change Drive Torque, Change Drive Direction, Speed Changing, Speed Reduction, Speed Increase |

| Layout: | Three-Ring |

| Hardness: | Hardened Tooth Surface |

| Installation: | Torque Arm Type |

| Step: | Stepless |

| Samples: |

US$ 9999/Piece

1 Piece(Min.Order) | |

|---|

Calculating Torque Requirements for a NEMA Gearbox

To calculate torque requirements for a NEMA gearbox, you need to consider factors like load type, speed, and efficiency. Use the formula: Torque (Nm) = (Power (W) × 1000) / (Speed (RPM) × Efficiency). Determine the required power and speed, and account for efficiency losses. Ensure that the calculated torque is within the gearbox’s rated torque capacity. It’s essential to factor in safety margins and dynamic loads for accurate results.

Safety Precautions when Working with NEMA Gearboxes

When working with NEMA gearboxes, ensure the power is off and locked out to prevent accidental startup, wear appropriate personal protective equipment (PPE) such as gloves and safety glasses, follow manufacturer guidelines for installation and maintenance, avoid wearing loose clothing or jewelry that can get caught, work in well-ventilated areas to prevent exposure to fumes, and be cautious of sharp edges and moving parts. Training and proper safety procedures are crucial to prevent accidents and injuries.

NEMA Gearbox Sizes

Yes, NEMA gearboxes come in various sizes, typically identified by a NEMA frame size. These sizes correspond to standard motor frame sizes and range from NEMA 23 to NEMA 56, with each size having specific dimensions and mounting configurations. It’s essential to choose the right NEMA gearbox size that matches your motor’s NEMA frame size for optimal compatibility and performance.

editor by CX 2024-03-30

China Professional Multi Stage Planetary Gearbox Inline Epicyclic Gear Reduction Drive NEMA Hydraulic Single Sun Planet Epicyclic Micro Motor Two Stage Precision Bevel Planetary gearbox drive shaft

Product Description

Multi stage planetary gearbox inline epicyclic gear reduction drive nema hydraulic single sun planet epicyclic micro motor 2 stage precision bevel planetary

Application of planetary gearbox

Planetary gearboxes are used in a wide variety of applications, including:

- Automotive: Planetary gearboxes are used in a variety of automotive applications, including transmissions, differentials, and power steering systems.

- Machine tools: Planetary gearboxes are used in machine tools to provide precise control of the speed and torque of the cutting tool.

- Robotics: Planetary gearboxes are used in robotics to provide the high torque and low speed required for precise motion control.

- Aerospace: Planetary gearboxes are used in aerospace applications, such as aircraft engines and landing gear systems.

- Construction: Planetary gearboxes are used in construction equipment, such as excavators and cranes.

- Medical: Planetary gearboxes are used in medical devices, such as surgical robots and endoscopes.

Planetary gearboxes are also used in a variety of other applications, such as:

- Wind turbines: Planetary gearboxes are used in wind turbines to convert the rotational motion of the turbine blades into electrical energy.

- Pumps: Planetary gearboxes are used in pumps to increase the pressure of the fluid being pumped.

- Conveyors: Planetary gearboxes are used in conveyors to move materials from 1 place to another.

- Winches: Planetary gearboxes are used in winches to lift and lower loads.

- Mixers: Planetary gearboxes are used in mixers to mix materials together.

Planetary gearboxes are a versatile and efficient type of gear train that can be used in a wide variety of applications. They offer a number of advantages over other types of gear trains, including:

- High efficiency: Planetary gearboxes are very efficient, meaning that they lose very little power as heat.

- Compact size: Planetary gearboxes are relatively compact, making them ideal for use in applications where space is limited.

- High torque: Planetary gearboxes can transmit a lot of torque, making them ideal for applications that require high power.

- Low noise: Planetary gearboxes are relatively quiet, making them ideal for use in applications where noise is a concern.

As a result of these advantages, planetary gearboxes are becoming increasingly popular in a wide variety of applications.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Toy, Agricultural Machinery, Car |

|---|---|

| Function: | Distribution Power, Clutch, Change Drive Torque, Change Drive Direction, Speed Changing, Speed Reduction, Speed Increase |

| Layout: | Three-Ring |

| Hardness: | Hardened Tooth Surface |

| Installation: | Torque Arm Type |

| Step: | Stepless |

| Samples: |

US$ 9999/Piece

1 Piece(Min.Order) | |

|---|

Troubleshooting Abnormal Noises in a NEMA Gearbox

If you encounter abnormal noises in a NEMA gearbox, first check for proper lubrication, inspect for damaged or worn components, listen for specific sounds like grinding or clicking to identify potential issues, ensure proper alignment and mounting, and refer to the manufacturer’s troubleshooting guide. If the issue persists, consult a professional technician to diagnose and address the problem.

Safety Precautions when Working with NEMA Gearboxes

When working with NEMA gearboxes, ensure the power is off and locked out to prevent accidental startup, wear appropriate personal protective equipment (PPE) such as gloves and safety glasses, follow manufacturer guidelines for installation and maintenance, avoid wearing loose clothing or jewelry that can get caught, work in well-ventilated areas to prevent exposure to fumes, and be cautious of sharp edges and moving parts. Training and proper safety procedures are crucial to prevent accidents and injuries.

Function of NEMA Gearboxes

A NEMA gearbox works by connecting a motor to mechanical equipment through a standardized interface. It adapts the motor’s output speed and torque to the requirements of the equipment, ensuring optimal performance. The gearbox contains gears that transmit power from the motor’s input shaft to the output shaft, adjusting the rotational speed and direction as needed. NEMA gearboxes come in various sizes and configurations to match specific motor and equipment combinations. They play a crucial role in power transmission, enhancing efficiency and reliability in industrial applications.

editor by CX 2024-03-29

China supplier Industrial Aluminium Stainless Steel Cast Iron NEMA Nmrv Worm Wheel Drive Motor Speed Reducer Reduction Gearbox sequential gearbox

Product Description

Technical data list:

| Type: | Worm Gear Speed Reducer |

| Model: | NMRV571–150 |

| Ratio: | 1:7.5,10,15,20,25,30,40,50,60,80,100 |

| Color: | Blue/Silver Or On Customer Request |

| Material | Housing: Blue-Coloured Cast-Iron Worm Gear-Copper-10-3# Worm-20CrMn Ti with carburizing and quenching, surface harness is 56-62HRC Shaft-chromium steel-45# |

| Lubricant: | Synthetic&Mineral |

| Bearing: | C&U Bearing |

| Seal: | high quality |

| Warranty: | -30-40°C |

| ICE FLANGE | 80B5,90B5,100B5,112B5,132B5,160B5 |

| Rated power: | 0.06KW,0.12KW,0.25KW,0.75KW,1.5KW,3KW,5.5KW,7.5KW |

| Application | Metallurgical machinery, food machinery, stage machinery, welding machinery, road machinery, amusement machines, packaging machinery, Rubber and plastic machinery, environmental protection machinery ,engineering machinery, construction machinery, machine tool industry, automotive industry, logistics and transportation and so on |

| NMRV | PAM | N | M | P | D | |||||||||||

| ICE | 5 | 7.5 | 10 | 15 | 20 | 25 | 30 | 40 | 50 | 60 | 80 | 100 | ||||

| 25 | 56B14 | 50 | 65 | 80 | 9 | 9 | 9 | 9 | 9 | 9 | 9 | 9 | 9 | |||

| 30 | 63B5 | 95 | 115 | 140 | 11 | 11 | 11 | 11 | 11 | 11 | 11 | 11 | 11 | |||

| 63B14 | 60 | 75 | 90 | |||||||||||||

| 56B5 | 80 | 100 | 120 | 9 | 9 | 9 | 9 | 9 | 9 | 9 | 9 | 9 | 9 | 9 | ||

| 56B14 | 50 | 65 | 80 | |||||||||||||

| 40 | 71B5 | 110 | 130 | 160 | 14 | 14 | 14 | 14 | 14 | 14 | 14 | 14 | ||||

| 71B14 | 70 | 85 | 105 | |||||||||||||

| 63B5 | 95 | 115 | 140 | 11 | 11 | 11 | 11 | 11 | 11 | 11 | 11 | 11 | 11 | 11 | 11 | |

| 63B14 | 60 | 75 | 90 | |||||||||||||

| 56B5 | 80 | 100 | 120 | 9 | 9 | 9 | 9 | |||||||||

| 50 | 80B5 | 130 | 165 | 200 | 19 | 19 | 19 | 19 | 19 | 19 | 19 | |||||

| 80B14 | 80 | 100 | 120 | |||||||||||||

| 71B5 | 110 | 130 | 160 | 14 | 14 | 14 | 14 | 14 | 14 | 14 | 14 | 14 | 14 | 14 | ||

| 71B14 | 70 | 85 | 105 | |||||||||||||

| 63B5 | 95 | 115 | 140 | 11 | 11 | 11 | 11 | 11 | ||||||||

| 63 | 90B5 | 130 | 165 | 200 | 24 | 24 | 24 | 24 | 24 | 24 | ||||||

| 90B14 | 95 | 115 | 140 | |||||||||||||

| 80B5 | 130 | 165 | 200 | 19 | 19 | 19 | 19 | 19 | 19 | 19 | 19 | 19 | ||||

| 80B14 | 80 | 100 | 120 | |||||||||||||

| 71B5 | 110 | 130 | 160 | 14 | 14 | 14 | 14 | 14 | ||||||||

| 71B14 | 70 | 85 | 105 | |||||||||||||

| 75 | 100/112B5 | 180 | 215 | 250 | 28 | 28 | 28 | |||||||||

| 100/112B14 | 110 | 130 | 150 | |||||||||||||

| 90B5 | 130 | 165 | 200 | 24 | 24 | 24 | 24 | 24 | 24 | 24 | ||||||

| 90B14 | 95 | 115 | 140 | |||||||||||||

| 80B5 | 130 | 165 | 200 | 19 | 19 | 19 | 19 | 19 | 19 | 19 | 19 | |||||

| 80B14 | 80 | 100 | 120 | |||||||||||||

| 71B5 | 110 | 130 | 160 | 14 | 14 | 14 | 14 | |||||||||

| 90 | 100/112B5 | 190 | 215 | 250 | 28 | 28 | 28 | 28 | 28 | 28 | ||||||

| 100/112B14 | 110 | 130 | 160 | |||||||||||||

| 90B5 | 130 | 165 | 200 | 24 | 24 | 24 | 24 | 24 | 24 | 24 | 24 | 24 | ||||

| 90B14 | 95 | 115 | 140 | |||||||||||||

| 80B5 | 130 | 165 | 200 | 19 | 19 | 19 | 19 | 19 | ||||||||

| 80B14 | 80 | 100 | 120 | |||||||||||||

| 110 | 132B5 | 230 | 265 | 300 | 38 | 38 | 38 | 38 | ||||||||

| 100/112B5 | 180 | 215 | 250 | 28 | 28 | 28 | 28 | 28 | 28 | 28 | 28 | 28 | ||||

| 90B5 | 130 | 165 | 200 | 24 | 24 | 24 | 24 | 24 | 24 | 24 | ||||||

| 80B5 | 130 | 165 | 200 | 19 | 19 | |||||||||||

| 130 | 132B5 | 230 | 265 | 300 | 38 | 38 | 38 | 38 | 38 | 38 | 38 | |||||

| 100/112B5 | 180 | 215 | 250 | 28 | 28 | 28 | 28 | 28 | 28 | 28 | ||||||

| 90B5 | 130 | 165 | 200 | 24 | 24 | |||||||||||

| 150 | 160B5 | 250 | 300 | 350 | 42 | 42 | 42 | 42 | 42 | |||||||

| 132B5 | 230 | 265 | 250 | 38 | 38 | 38 | 38 | 38 | 38 | |||||||

| 100/112B5 | 180 | 215 | 200 | 28 | 28 | 28 | 28 | |||||||||

Components:

1. Housing: Die-cast Aluminum Alloy Gearbox (RV571~RV090)

Cast Iron Gearbox (RV110~RV150)

2. Worm Wheel: Wearable Tin Bronze Alloy, Aluminum Bronze Alloy

3. Worm Shaft: 20Cr Steel, carburizing, quenching, grinding, surface hardness 56-62HRC, 0.3-0.5mm remaining carburized layer after precise grinding

4. Input Configurations:

Equipped with Electric Motors (AC Motor, Brake Motor, DC Motor, Servo Motor)

IEC-normalized Motor Flange

Solid Shaft Input

Worm Shaft Tail Extension Input

5. Output Configurations: Keyed Hollow Shaft Output

Hollow Shaft with Output Flange

Plug-in CHINAMFG Shaft Output

6. Spare Parts: Worm Shaft Tail Extension, Single Output Shaft, Double Output Shaft, Output Flange, Torque Arm, Dust Cover

7. Gearbox Painting:

Aluminum Alloy Gearbox:

After Shot Blasting, Anticorrosion Treatment and Phosphating, Paint with the Color of RAL 5571 Gentian Blue or RAL 7035 Light Grey

Cast Iron Gearbox:

After Painting with Red Antirust Paint, Paint with the Color of RAL 5571 Gentian Blue

Workshop show

FAQ

Q 1. What is your terms of packing?

A: Generally, we pack our goods in single color box. If you have special request about packing, pls negotiate with us in advance, we can pack the goods as your request.

Q2. What is your terms of payment?

A: T/T 30% as deposit, and 70% before delivery. We’ll show you the photos of the products and packages

before you pay the balance. Other payments terms, pls negotiate with us in advance, we can discuss.

Q3. What is your terms of delivery?

A: EXW, FOB, CFR, CIF.

Q4. How about your delivery time?

A: Generally, it will take 25 to 30 days after receiving your advance payment. The specific delivery time depends

on the items and the quantity of your order.

Q5. Can you produce according to the samples?

A: Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures.

Q6. What is your sample policy?

A: We can supply the sample if we have ready parts in stock, but the customers have to pay the sample cost and

the courier cost.We welcome sample order.

Q7. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery

Q8: How do you make our business long-term and good relationship?

1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them,

no matter where they come from. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Toy, Agricultural Machinery |

|---|---|

| Function: | Distribution Power, Clutch, Change Drive Torque, Change Drive Direction, Speed Changing, Speed Reduction, Speed Increase |

| Layout: | Coaxial |

| Hardness: | Hardened Tooth Surface |

| Installation: | Torque Arm Type |

| Step: | Single-Step |

| Samples: |

US$ 20/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Replacing Parts of a NEMA Gearbox vs. Replacing the Whole Unit

Replacing parts of a NEMA gearbox is a common practice if specific components are worn or damaged. However, it’s essential to consider factors like the availability of replacement parts, the cost-effectiveness of repairs, the overall condition of the gearbox, and the expertise required for the replacement. In some cases, replacing the whole unit might be more practical, especially if the gearbox has a history of issues or if the cost of repairs exceeds the cost of a new unit. Consulting with a gearbox specialist can help make an informed decision.

Lifespan of a Typical NEMA Gearbox

The lifespan of a NEMA gearbox can vary widely depending on factors such as quality, maintenance, load conditions, and operating environment. On average, a well-designed and properly maintained NEMA gearbox can last anywhere from 10,000 to 50,000 hours of operation. Regular maintenance, proper lubrication, and addressing any issues promptly can significantly extend the gearbox’s lifespan.

NEMA Gearbox Sizes

Yes, NEMA gearboxes come in various sizes, typically identified by a NEMA frame size. These sizes correspond to standard motor frame sizes and range from NEMA 23 to NEMA 56, with each size having specific dimensions and mounting configurations. It’s essential to choose the right NEMA gearbox size that matches your motor’s NEMA frame size for optimal compatibility and performance.

editor by CX 2024-03-29

China Professional NEMA Gearbox Motor Drive Wheel Winch Box Best Assembly Right Angle Nmrv Stainless Steel NEMA Interchange Transmission Parts Industrial Small Worm NEMA Gearbox bevel gearbox

Product Description

Nema Gearbox Motor Drive Wheel Winch Box Best Assembly Right Angle Nmrv Stainless Steel NEMA Interchange Transmission Parts Industrial Small Worm Nema Gearbox

Wormwheel gearboxes go by several names, including 90-degree gearboxes, right angle gearboxes, speed reducers, worm gear reducers and worm drive gearboxes. Gear reduction boxes feature a gear arrangement in which a gear in the form of a screw, also known as a worm, meshes with a worm gear. These gears are typically made from bronze and the worms are steel or stainless steel.

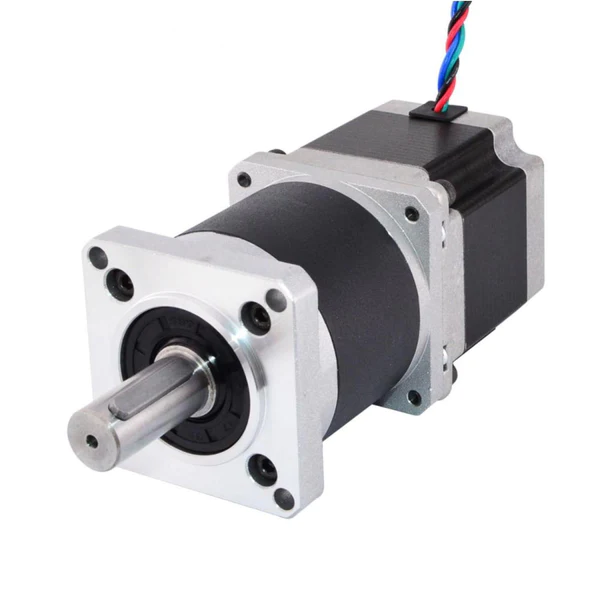

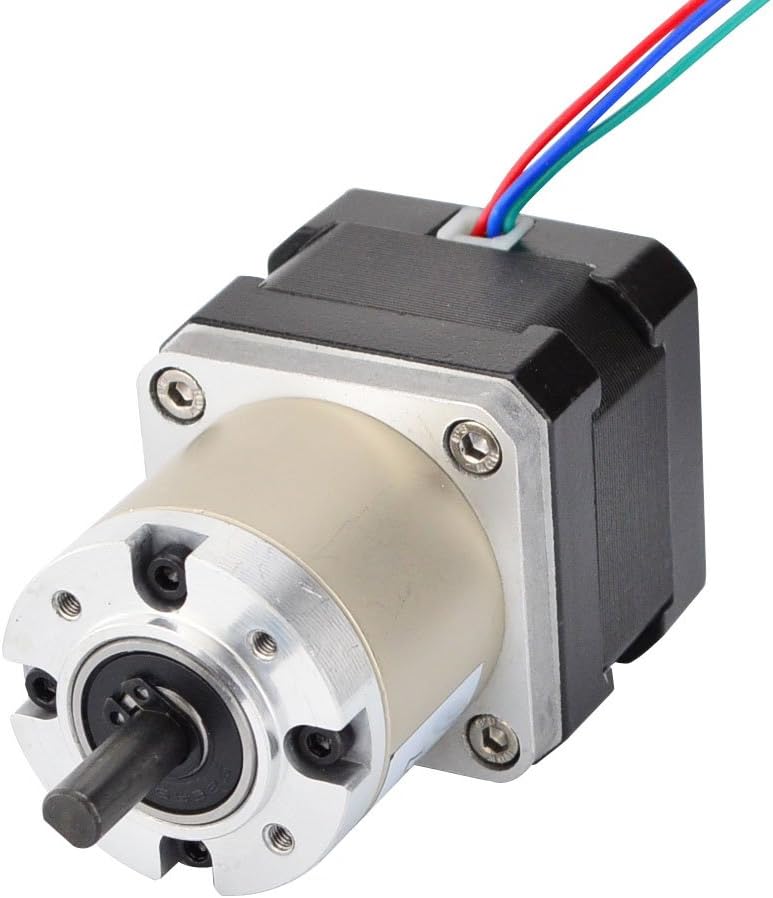

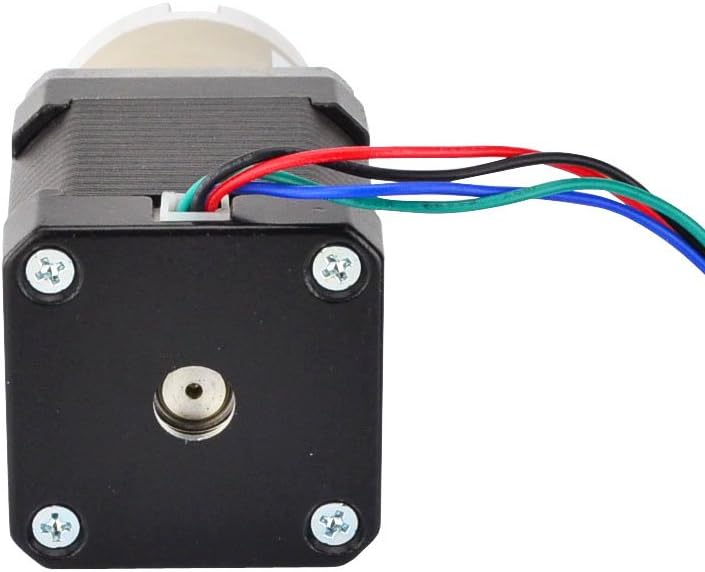

Product description

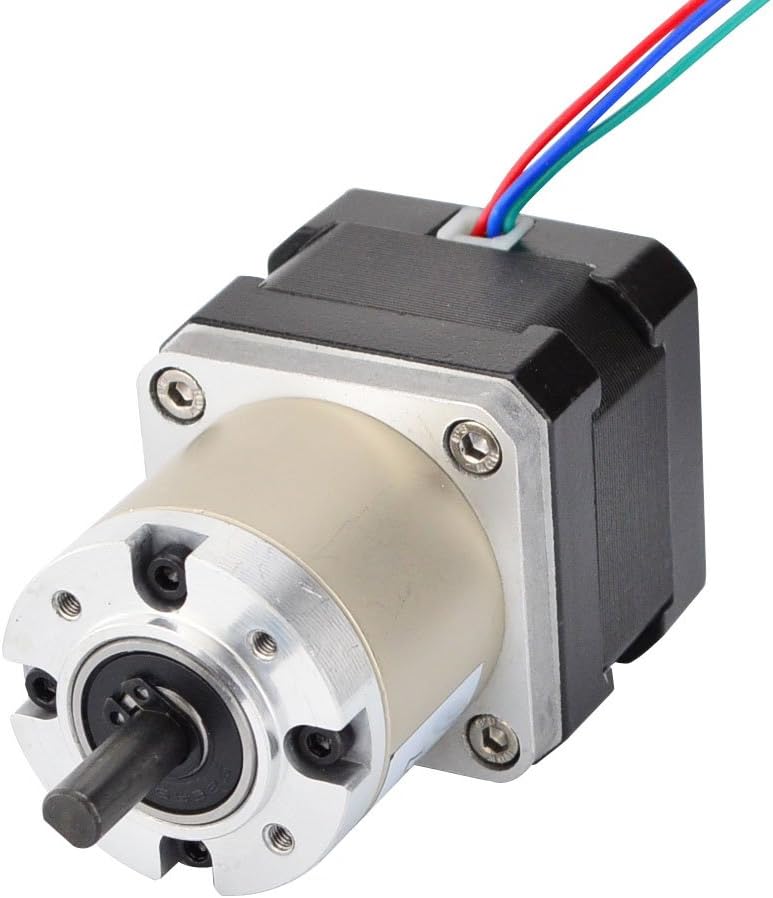

Size:10:1

Nema23 Worm Gear Stepper Motor Gearbox Ratio 7.5:1 10:1 20:1 30:1 50:1 L76mm 3A 1.8Nm Motor for CNC

Package Included :

1 x Nema23 L76mm Stepper Motor

1 x Gearbox

Item Specifications :

4 wires : Blue , Black , Green , Red

Step Angle : 1.8degree

Holding Torque : 1.8Nm

Current : 3A

Gear Ratio : 7.5:1, 10:1, 20:1, 30:1, 50:1

Motor Length : L76mm

Application of Nema Gearbox

NEMA gearboxes are used in a wide variety of applications, including:

- Machine tools: NEMA gearboxes are used to power a variety of machine tools, such as lathes, mills, and drills. They provide the torque and speed control needed for these machines to operate efficiently.

- Conveyors: NEMA gearboxes are used to power conveyors, which are used to transport materials in a variety of industries, such as manufacturing, food processing, and logistics.

- Pumps: NEMA gearboxes are used to power pumps, which are used to move fluids in a variety of applications, such as water treatment, wastewater treatment, and oil and gas production.

- Fans: NEMA gearboxes are used to power fans, which are used to circulate air in a variety of applications, such as heating, ventilating, and air conditioning (HVAC).

- Actuators: NEMA gearboxes are used to power actuators, which are used to move objects in a variety of applications, such as robotics, automation, and aerospace.

NEMA gearboxes offer a number of advantages over other types of reducers, including:

- Smoother operation: NEMA gears mesh more smoothly than other types of gears, which results in less noise and vibration.

- Longer life: NEMA gears are less prone to wear and tear than other types of gears, which results in a longer service life.

- Higher efficiency: NEMA gearboxes are more efficient than other types of reducers, which results in lower energy consumption.

As a result of these advantages, NEMA gearboxes are a popular choice for a wide variety of applications.

Here are some additional benefits of using NEMA gearboxes:

- They are relatively easy to install and maintain.

- They are available in a variety of sizes and ratings to meet the needs of different applications.

If you are looking for a reliable, efficient, and versatile gearbox, a NEMA gearbox is a great option.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Toy, Agricultural Machinery, Car |

|---|---|

| Hardness: | Soft Tooth Surface |

| Installation: | 90 Degree |

| Layout: | Coaxial |

| Gear Shape: | Conical – Cylindrical Gear |

| Step: | Stepless |

| Samples: |

US$ 9999/Piece

1 Piece(Min.Order) | |

|---|

Preventing Overheating in a NEMA Gearbox

To prevent overheating in a NEMA gearbox, you can take several measures. Proper lubrication is crucial to reduce friction and heat generation. Choose the right type of lubricant and ensure it’s at the correct level. Adequate ventilation around the gearbox is important, as well as avoiding external heat sources. Monitoring the gearbox’s temperature using sensors can provide early warnings. If the gearbox is consistently running at high temperatures, consider adjusting the load, gear ratio, or using a gearbox with a higher thermal capacity. Regular maintenance, including cleaning and inspecting cooling systems, can also help prevent overheating.

Maintaining and Servicing a NEMA Gearbox

Maintaining and servicing a NEMA gearbox involves regular inspections, proper lubrication, and addressing any issues promptly. Follow the manufacturer’s maintenance schedule and guidelines. Keep the gearbox clean and free from debris, and check for any leaks or unusual noises. Lubricate according to specifications with the recommended lubricant. Replace worn or damaged parts, such as seals or bearings, as needed. Regularly monitor temperature and vibration levels. Proper maintenance can prolong the gearbox’s life and prevent costly breakdowns.

Key Features of NEMA Gearboxes

NEMA gearboxes feature a standardized mounting interface that ensures compatibility with NEMA motors. They are designed to provide efficient power transmission, torque multiplication, and speed reduction. These gearboxes are constructed from durable materials, such as cast iron or aluminum, to withstand varying loads and conditions. They often include precision-machined gears for smooth operation and reduced noise. NEMA gearboxes come in various gear ratios to accommodate different speed and torque requirements. They also offer options for different mounting orientations and motor flange sizes. These features collectively make NEMA gearboxes versatile and suitable for a wide range of industrial applications.

editor by CX 2024-03-29

China wholesaler NEMA 23 Worm Gearbox Gear Box Wheel High Quality Speed Reduction Jack Best Steering High Quality Good Price Gear Manufacturer Industrial NEMA 23 Worm Gearbox components of gearbox

Product Description

Nema 23 Worm Gearbox Gear Box Wheel High Quality Speed Reduction Jack Best Steering High Quality Good Price Gear Manufacturer Industrial Nema 23 Worm Gearbox

Application of Worm Gearbox

Worm gearboxes are used in a wide variety of applications where high torque and low speed are required. Some of the most common applications include:

- Conveyors: Worm gearboxes are used to power conveyors, which are used to transport materials in a variety of industries, such as manufacturing, food processing, and logistics.

- Pumps: Worm gearboxes are used to power pumps, which are used to move fluids in a variety of applications, such as water treatment, wastewater treatment, and oil and gas production.

- Fans: Worm gearboxes are used to power fans, which are used to circulate air in a variety of applications, such as heating, ventilating, and air conditioning (HVAC).

- Actuators: Worm gearboxes are used to power actuators, which are used to move objects in a variety of applications, such as robotics, automation, and aerospace.

- Elevators: Worm gearboxes are used to power elevators, which are used to transport people and goods between different floors of a building.

- Security gates: Worm gearboxes are used to power security gates, which are used to control access to a building or area.

- Worm drive saws: Worm gearboxes are used to power worm drive saws, which are used to cut wood, metal, and other materials.

Worm gears offer a number of advantages over other types of gear reducers, including:

- High torque: Worm gears can generate high torque, which makes them ideal for applications where heavy loads need to be moved.

- Low speed: Worm gears operate at low speeds, which makes them ideal for applications where smooth and controlled movement is required.

- Compact size: Worm gearboxes are typically smaller than other types of gear reducers, which makes them ideal for applications where space is limited.

- Low maintenance: Worm gears require very little maintenance, which makes them a cost-effective choice for many applications.

Here are some of the limitations of worm gears:

- Low efficiency: Worm gears are not as efficient as other types of gear reducers, which can lead to increased energy costs.

- High noise levels: Worm gears can be noisy, which can be a concern in some applications.

- High maintenance costs: Worm gears require more frequent maintenance than other types of gear reducers, which can increase overall costs.

Despite these limitations, worm gears remain a popular choice for a wide variety of applications due to their high torque and low speed capabilities.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Agricultural Machinery, Car |

|---|---|

| Function: | Distribution Power, Clutch, Change Drive Torque, Change Drive Direction, Speed Changing, Speed Reduction, Speed Increase |

| Layout: | Coaxial |

| Hardness: | Hardened Tooth Surface |

| Installation: | Horizontal Type |

| Step: | Steel |

| Samples: |

US$ 9999/Piece

1 Piece(Min.Order) | |

|---|

Cost of a NEMA Gearbox

The cost of a NEMA gearbox varies widely based on factors like size, type, brand, and features. Smaller, less complex models might start around $100, while larger and more specialized units can range from hundreds to thousands of dollars. Customization, additional accessories, and quality can also influence the price. It’s advisable to request quotes from suppliers or manufacturers for accurate pricing information.

Lubrication for NEMA Gearbox

NEMA gearboxes require proper lubrication to ensure smooth operation and longevity. It’s recommended to use the lubricant specified by the manufacturer, typically a high-quality industrial gear oil. Properly fill the gearbox with the recommended lubricant, ensuring it reaches the correct level as indicated by the manufacturer. Regularly check and maintain the lubrication level according to the manufacturer’s guidelines to prevent overheating and wear.

Using NEMA Gearboxes

A NEMA gearbox is used for adapting and connecting motors to various mechanical equipment and applications. It provides a standardized interface between motors and equipment, ensuring compatibility and efficient power transmission. NEMA gearboxes are commonly used in industrial settings for tasks such as conveying, mixing, pumping, and material handling. They help optimize the power and torque transfer from the motor to the equipment, enabling smooth and reliable operation.

editor by CX 2024-03-28